Hot Vulcanising Machine – Hydraulic and Pressure Bag

We offer these Belt Vulcanizing Machines which are fabricated using advanced and modern technologies. They are light in weight, easily available and well known for robust construction and smooth operation. Clients can avail a customer requirement and for industry leading prices. These are highly durable and contain high performance. This is the process of skiving back the layer of the conveyor belts, adding uncured rubber and vulcanizing them back together in a heat press. This is the strongest and longest splice available.

The most common way to do this splice is for us transport the press to your site and vulcanize the belt into your system, also excellent system when belt cleaners/scrapers, or more magnets or in place on your system. the hot vulcanize is also easier on your pulleys and conveyor system is general. All vulcanizing presses are designed to customer’s requirements for belt widths, splice lengths, combinations, voltages, configurations, etc.

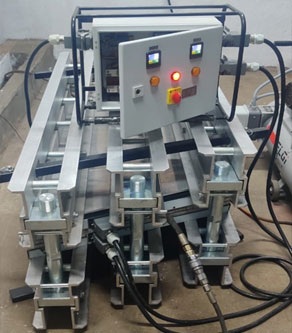

Hydraulic Press

Platens are designed to be used in combination or stand alone. Heating plates and cross beam made of light aluminium alloy. Method of heating is Through Tubular heating elements. Designed for hydraulic presses for Rhombic splice (16° 42’; 22°) or rectangular splices (90°).

Cross Beam is Compact, light metal cylinders provide high-pressure for even surface pressure. Digital display of temperature controller shows exact temperature reading in each heating plate via PT 100 thermo-sensor. Quick and simple pressure build-up using a reciprocating piston hand pump or a motor-driven pump unit. Electronic controller for quick and simple programming of temperature. Digital display for set and actual temperatures .

Pressure Bag Press

The lightweight heating mat used for excellent thermal conductivity. Heating plates and cross beam made of light aluminium alloy. Designed pressure bag press for Rhombic splice (16° 42’; 22°) or rectangular splices (90°).

High strength fabric reinforced pressure bag to withstand high-pressure for uniform surface pressure. Air or Water to be used as a pressurizing medium in a pressure bag. Digital display of temperature controller shows exact temperature reading in each heating plate via PT 100 thermo-sensor.

Quick and simple pressure build-up using an air pump or water pump unit. Electronic controller for quick and simple programming of temperature. Digital display for set and actual temperatures. End bolts are designed within the crossbeam profile providing higher safety. Safety pin to be provided for the end bolt.